Bioprosthetic heart valves, which are also known as tissue valves, are the prostheses made entirely of animal or human tissues. BHVs are divided into 3 groups: xenograft, allograft and autograft.

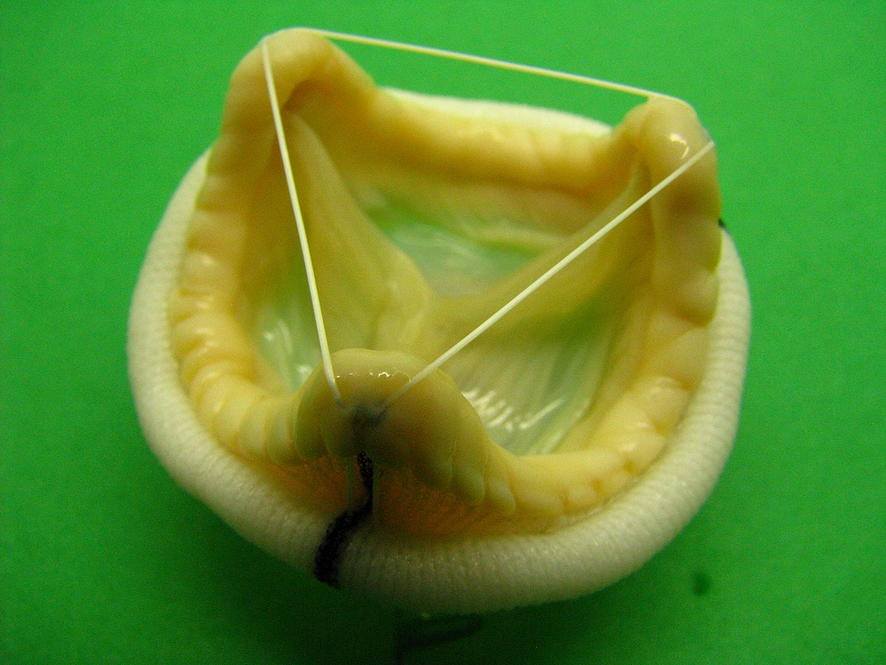

Xenografts are those made of animal tissues. Two candidate animals, pigs and cows, are commonly used for bioprosthetic aortic valves. Xenograft valves harvested from pigs are known as porcine, and those harvested from cows are known as bovine valves. Porcine valves are basically the aortic valve harvested from pigs and have a similar structure to that of humans. This is simply because several components of the cardiovascular system in pigs, such as the heart structure, systemic pressure, aortic heart valve, mitral valve, and the aortic root is similar to those of humans. Bovine valves are made of the precordium tissue harvested from cows. In fact, only the leaflets are made of pericardial tissue, which will be attached later on to a synthetic stent. In terms of the design procedure, porcine valves are one step ahead of bovines, simply because porcine valves are already a valve, whereas bovine valves should be designed and fabricated in a form of a valve.

Allografts are those harvested from a cadaver. They are excellent alternatives for bioprosthetic valves but are not readily available at the right size and time when needed.

Autografts are harvested from a patient’s own body, in which the patient’s pulmonary valve is moved to the aortic position through the Ross Procedure. The Ross procedure, also known as a pulmonary autograft, is a cardiac surgery in which a diseased aortic valve is substituted with the patient’s own pulmonary valve. A pulmonary allograft or any other prosthetic valve is then used as the patient’s pulmonary valve. This operation is more often recommended in infants and children, but is not uncommon in adults as well.

The arrival of tissue valves is associated with the introduction of glutaraldehyde for the fixation of biological tissue by Dr. Carpentier in 1969. The tissue treatment with glutaraldehyde is essential for the design and fabrication of bioprosthetic valves, including porcine and bovine pericardium valves, which are made of animal tissues. The main issue with the animal tissues used in the structure of prosthetic valves is the potential of thrombogenic complications. In 1970, the Hancock standard porcine BHV was implanted in the aortic position. After a while, the Hancock modified orifice (MO) BHV was introduced in order to address the high post-implantation gradients associated with small-size valves in the aortic position. The issue was due to the bulky muscle under the right coronary leaflet. In this model, a composite valve is designed where the right coronary leaflet is replaced with a leaflet from another valve, with the muscle bar already removed. After this model, the Carpentier-Edwards standard porcine BHV was introduced in 1975. The consecutive generations of BHVsconsist of the Carpentier-Edwards supraannular (SAV) porcine model, which was introduced in 1981; the Hancock II porcine model, which has been available since 1982; and the Medtronic intact porcine model, which was introduced in 1985. These BHV models are known to offer improved zero-pressure fixation that maintains delicate but significant histologic features of the valve leaflets, along with anti-mineralization treatments to decrease calcification-oriented deterioration of the valve tissue. The idea is to provide the new designs with a more flexible, lower-profile stent and smaller sewing rings, which can essentially lead to a larger orifice area.